DIAPHRAGM SEAL SERVICES

Colonial Instruments, Inc. offers Full Service Diaphragm Seal Filling and Assembly. We are also and Authorized Wika Diaphragm Seal Service Center. We stock a wide variety of Wika diaphragm seal component parts for the model L990.10 and L990.TC (threaded) and L990.12 and L990.FA (flanged). We can quickly build up and ship various configurations of the above models and pair with the instrument of your choice. We can also add in options, such as, pressure snubbers or pulsation dampeners, integral cooling elements for high temperature applications, or capillary assemblies for remote mounting, and locking wire to prevent removal of instruments, which could compromise the filled system.

We also can build multi-instrument assemblies with our proprietary Low Volume Instrument Tees (LVIT) and Low Volume Instrument Manifolds (LVIM). These are machined from solid bar or hex stock 316L stainless steel, and have 0.156” bores, which cut down on the overall volume of fluid in the assembly and relives some temperature effect error due to volumetric expansion of the fill fluid.

SERVICE DETAILS

We use PST Loctite on the threaded connections on all of our assemblies. We find this to be cleaner and better sealing that standard PTFE, all connections of the filled system are given a bead of yellow lacquer seal after testing has been completed, this allows for quickly assessment of whether an instrument has been removed or connection has been broken (turned), thus compromising the system fill and rendering the unit inoperable.

All units are filled in our proprietary vacuum chamber. We have found that using a vacuum chamber assures that the diaphragm element of the seal is “neutral” when filling. Depending on the fill fluid choice, we typically pull a vacuum down to 200 millitorr or greater. We heat and stir the fluids to assure that they are properly degassed, giving a better fill. Any trapped gases in the fill fluid become compressible, and will more readily expand when temperature is increased. Both of these variables can lead to errors in pressure measurement. Proper degassing of system fill fluids can virtually eliminate the aforementioned errors.

All units are pressure tested after the filling process has been completed. We check for any leaks in the sealed system and verify that complete instrument/seal assembly is within manufacturer’s accuracy specifications. For an additional charge, we can provide a certificate of conformance to procedure and drawings (batch certificate for order) or we can provide a traceable calibration certificate (individual certificate per instrument / assembly).

We also offer custom piping assemblies for both the process and flushing connections of assemblies, in either brass or 316 stainless steel fitting and valves. All process and flushing piping assemblies use PTFE tape on threaded connections.

MISSION STATEMENT

We strive for the highest quality on our diaphragm seal assemblies. Always trying to assure you get, a properly selected diaphragm seal / instrument combination that will work and read accurately, be leak free and properly assembled.

We can also assemble customer provided instruments and diaphragm seal, and our competent and knowledgeable process instrument specialists will work with you to make sure that the instruments and diaphragm seal that you are providing will work properly for the application demands you have.

We offer repair service for damaged or ill functioning assemblies. Many time we find that a system fill has been compromised, typically due to an operator accidentally removing and instrument or turning a connection (tightening a connection will compress the fluid and make a pressure instrument read above zero and loosening a fitting will cause a leak, which will result in the instrument reading slowly or not at all). An assembly may have damage due to corrosion, or an instrument may simply need calibration. Whatever the cause, we can help. Send in your complete assembly and we will evaluate and provided you with an estimate cost for the repair and any replacement parts or instruments necessary.

DIAPHRAGM SEAL ASSEMBLY OPTIONS & CONFIGURATIONS

Low Volume Instrument Tee (LVIT)

For multi-instrument assemblies we provide our proprietary Low Volume Instrument Tees (LVIT).

These are machined from solid bar or hex stock 316L stainless steel, and have 0.156” bores, which cut down on the overall volume of fluid in the assembly and relives some temperature effect error due to volumetric expansion of the fill fluid.

Low Volume Instrument Manifold (LVIM)

Our latest product that we now offer for multi-instrument assemblies is our proprietary Low Volume Instrument Manifold (LVIM). These were developed to replace the old “Goal Post” configuration. They are great for instrument configurations where both instruments have displays that require the instrument to be in an upright position.

These are machined from solid bar or hex stock 316L stainless steel, and have 0.156” bores, which cut down on the overall volume of fluid in the assembly and relives some temperature effect error due to volumetric expansion of the fill fluid. They are offered in both 1/4″ NPT and 1/2″ NPT connection sizes.

Piping Assemblies

We can provide pre-fabricated piping assemblies, which can be shipped assembled or separately from the diaphragm seal assembly. This cuts down on installation time in the field and many times in Waste Water and Water Treatment specifications we find that there are requirements for the units to come pre-assembled with piping. Piping is available in many different configurations both for flushing ports and off the process connection of the diaphragm seal), connection sizes and shut off valve specifications. Next time you come across a drawing or specification that calls for a “piping tree” you know who to call.

Cooling Elements

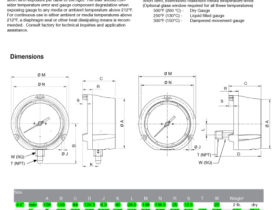

Excessive exposure to heat can cause your pressure gauges and pressure transmitters to read inaccurately. Most Bourdon tube pressure gauges will exhibit an additional 0.4% error in span for every 18°F above reference conditions (68°F). For example, if your instrument is running at a temperature of 200°F that’s an additional 3% error in reading added to the manufacturer’s stated accuracy. Keep your instruments accurate on critical applications by using diaphragm seals and properly selected additional heat dissipating elements.

We offer both the Wika 4″ finned cooling element (Rated to 500°F) and the 8″ perforated cooling element (Rated to 750°F) in both 1/4″ NPT and 1/2″ NPT, or can provide them welded to the diaphragm seal upper housing for particularly aggressive and critical applications, where fugitive emissions may be a concern.

Capillary Assemblies

Capillary assemblies are a great way to remote mount and instrument, measure level in a DP application, and can also protect and instrument from heat. There are many variables that need to be considered when selecting a capillary assembly. Aside from the standard “length, connection sizes, and material of the capillary”, there are factors such as, capillary internal diameter, proper fill fluid selection, calibration offset for positive or negative head pressure, and many more. Let us do the heavy lifting. If you can get us some simple details about the process, we’ll take care of the rest.

Accessories

All of the above categories are really just “accessories” for diaphragm seals. They are basically, enhancements or upgrades, that are designed to solve a problem and protect you valuable instrument, and above all, ensure that instrument is reading accurately.

Detailed in the tabs above you found several options to accessorize. Some other accessories you may consider would be:

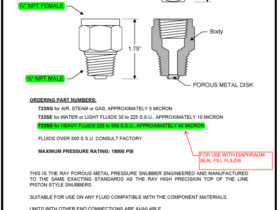

Snubber – A simple porous disc snubber or piston snubber is a great way to protect you instrument from pulsation and get more stable readings.

Pressure Limiting Valve (PLV) – is a device that is designed as a self-operating pressure shut off valve. It can be set at a specific pressure where it will shut off the pressure to the instrument and protect it from over pressure damage. These work very well when paired with a snubber, as it give the PLV more time to respond to a sudden pressure spike.

Lockwire – is simply a piece of wire that is attached to the instrument and diaphragm seal that is designed to deter an operator in the field, from removing or turning the instrument, compromising the fill of the sealed system.

Flushing Ring – is designed to be used in conjunction with a fanged diaphragm seal. It is basically a wafer style ring that fits between a specific sized flange. It sits under the diaphragm seal and can be machined with one or more flushing or test ports. These would typically be used for viscous process media or where particulates may be present and periodic back flushing is required. Another application would be to use the flush ring as an access point for the use external calibration.

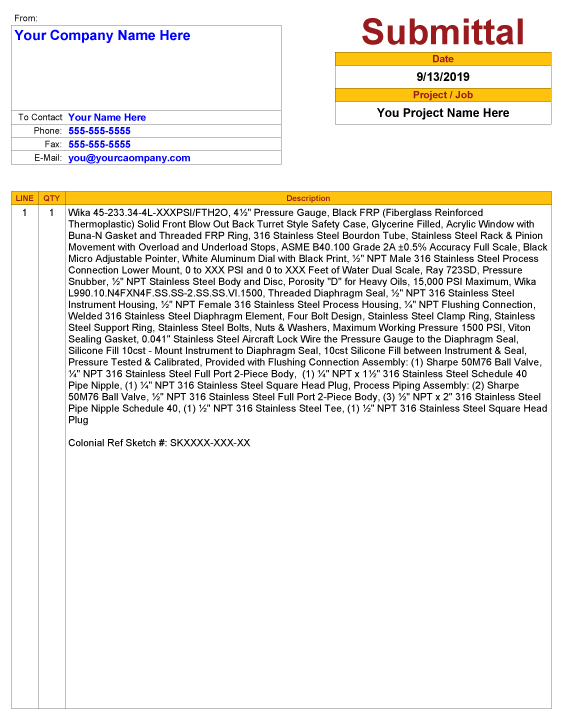

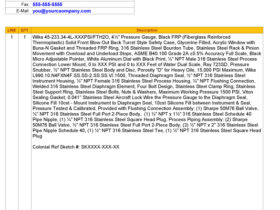

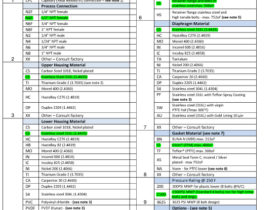

Example Submittal Package

Pictured above in an example of a typical submittal package that we provide at Colonial Instruments when requested. We make the submittal cover out with your pertinent company information, including name, phone, and email. With diaphragm seal assemblies we include a “shop sketch”, which is identified by a sketch number, which is also referenced, on the cover section, by line item. If there are multiple sketches for a project you and your client can easily reference the various drawings associated with each item.

DIAPHRAGM SEAL FILL FLUIDS

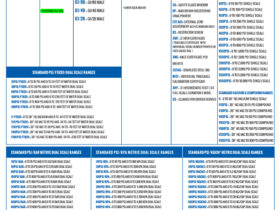

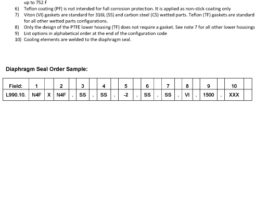

| Fluid Type | Temp Range Pressure (≥ 15PSIA) | Temp Range Vacuum (<15 PSIA) | Viscosity (cSt at 70°F {21°C}) | Notes |

|---|---|---|---|---|

| 10 cSt Silicone Fill (Standard) | -40°F to 392°F | -40° to 250°F | 10 cSt | |

| 50 cSt Silicone Fill | -40°F to 392°F | -40° to 250°F | 50 cSt | |

| 350 cSt Silicone Fill | 0°F to 372°F | Not Suitable | 350 cSt | FDA Approved (Food Grade) |

| High Temp Silicone 550 Fill | -4°F to 550°F | -4°F to 350°F | 125 cSt | High Temp to 550°F |

| High Temp Silicone KN3.2 Fill | -4°F to 750°F | -14°F to 392°F | 39 cSt | High Temp to 750°F |

| Low Temp 4cSt Silicone Fill | -130°F to 356°F | -130°F to 176°F | 4 cSt | Low Temp to -130°F |

| Glycerine Fill | 60°F to 462°F | Not Suitable | 1,300 cSt | FDA Approved (Food Grade) – Not for Vacuum |

| Neobee M-20 Fill | -10°F to 392°F | -10°F to 200°F | 10 cSt | FDA Approved (Food Grade) |

| Mineral Oil Fill | -4°F to 482°F | -4° to 338°F | 75 cSt | FDA Approved (Food Grade) |

| Halocarbon 6.3 Fill | -40°F to 347°F | -40°F to 176°F | 6.3 cSt | For Oxygen and Chlorine |

| Fluorolube FS-5 | -40°F to 392°F | -40°F to 176°F | 5 cSt | For Oxygen and Chlorine |